Why calibration is more than just a measurement check

Measuring instruments are the backbone of countless industrial, medical, and research applications. But like any technical system, they are subject to wear, temperature fluctuations, and environmental influences. Even the smallest deviations can result in incorrect readings – with potentially serious consequences:

🔍 The bottom line: Regular calibration ensures that measuring instruments operate reliably and accurately – and protects companies from financial and legal consequences.

How does a calibration process work?

Many companies know calibration is important, but not what it actually involves. The process is strictly standardized and includes several steps:

📌 Important: Calibration does not change or manipulate the device – it simply determines how accurate the instrument still is. Adjustment is optional and can be added to the service.

How often should a device be calibrated?

There is no universal rule for calibration intervals – it depends on the application, instrument type, and applicable regulations.

General recommendations:

💡 Our tip: We help you develop a custom calibration plan that saves costs while ensuring maximum accuracy. You can also activate our automatic calibration reminder – so you’ll never miss a due date and stay fully compliant!

What regulations apply to calibration?

Many industries are subject to strict requirements for measurement accuracy:

👉 Not sure which standards apply to your case? We’re happy to advise and help you meet all legal requirements.

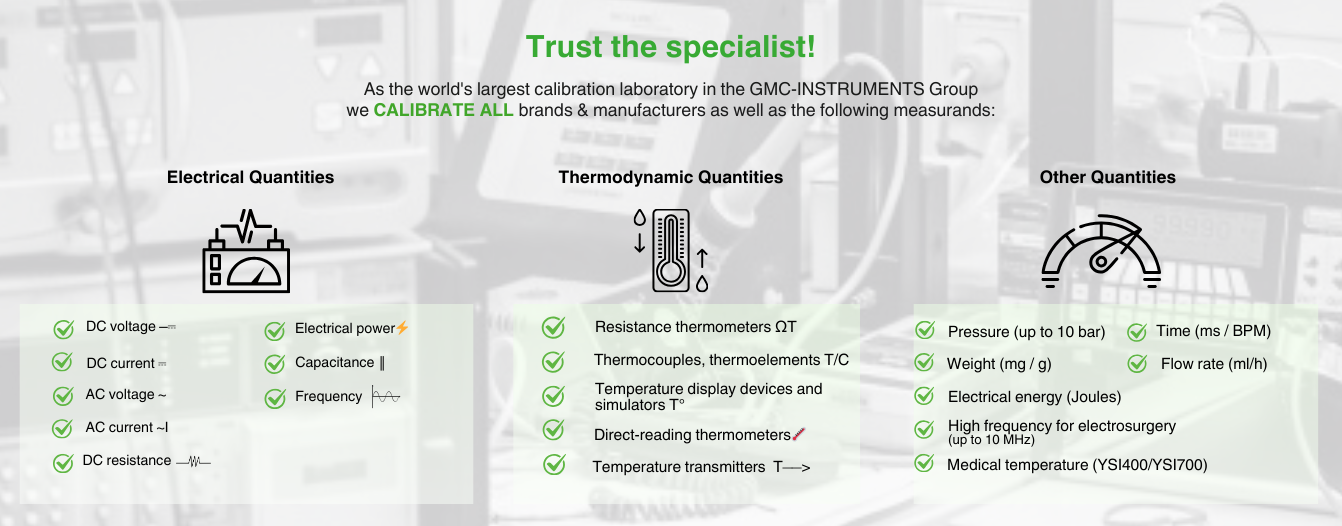

Why GMC-I Service? More than just calibration

We understand that calibration is not "just a certificate" – it’s a strategic decision for quality, safety, and efficiency. That’s why we offer:

📌 Book your calibration today and ensure your measurement accuracy!

🔗 Request now: Commissioning

GMC-I Service GmbH

Beuthener Straße 41

D-90471 Nürnberg

Tel.: +49 911 817718-0

Fax: +49 911 817718-253

Mo-Th 8:00 - 16:30 Uhr

Fr 8:00 - 13:00 Uhr

For you to download

Details about the order you can find here.

If you have any questions, please feel free to write to us or use our contact form.

GMC-I Service GmbH

Telephone:+49 911 817718 - 0